SAPPHIRE TUBES FOR HIGH-TEMPERATURE THERMOCOUPLES

Sapphit sapphire tubes are the material of choice for the protection of high-temperature thermocouples in corrosive environment.

Single crystal sapphire tubes represents a perfect durable alternatice to alumina ceramics (polycrystalline corundum ceramics). Unlike ceramics, single crystal provides 100% gas tightness and higher resistance against corrosion. Customers benefits from higher reliability and from prolonged periods between thermocouple replacements (typically 4x longer) and system shutdowns.

Key properties

- 100% gas-tightness - no pores, perfect environmental insulation prevents the diffusion of ambient atmosphere to the thermocouple

- High resistance to aggressive environments

- Operating temperatures up to 2000°C - sapphire tubes maintain their characteristics and shape up to its melting point, unlike ceramicr, sapphire tubes do not bend at high temperatures

- High operating pressures - sapphire tubes generally withstand dozens bar of pressure

- Outstanding electro-insulation properties

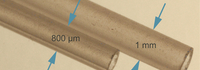

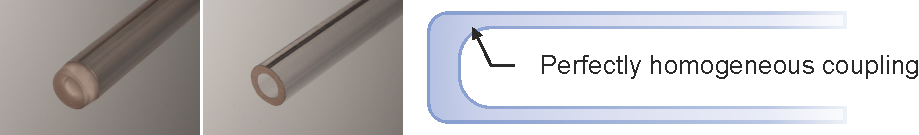

Sapphire thermocouple set consists of the outer one-side sealed protective sapphire tube and one or more inner capillaries used for insulation of branches of the thermocouple.

Thermocouple wire protection

Branches of thermocouple must be electrically insulated and protected against high-temperature corrosion. Even very low concentration of some substances (lead, …) significantly shorten lifetime of the thermocouple wire. Typically, thermocouple is inserted to ceramic and/or metallic sheath. These materials are chosen according to temperatures and chemical composition of the environment. Sapphire tubes successfully substitute the ceramics tubes that are not resistive against diffusion of metals.

|

|

| Lead oxide diffudes through multiple ceramic tubes. | Lead oxide is stopped by the single crystal sapphire tube outside protection tube. Inside tube remains perfectly intact. |

Durability of thermocouples protected by single crystalline sapphire tubes is much higher then in the case of standard ceramics tubes. Even protective tubes of small diameters are sufficiently strong and high temperature resistant. The sapphire caps for thermocouples are the economical choice in many processes and applications such as:

- refineries

- cracking units

- combustion reactors

- incinerators

- chemical industry

- glass industry

- semiconductor industry - clean process treatment

|

|

|

| Sapphit™ probe inserted in moving stream of lead crystal at 1170°C after 25 month. | Sapphit™ probe in glass furnace crown at 1500°C for 11 month. No signs of wear. | Sapphit™ probe retracted from gasification unit |

Sapphire thermocouple design

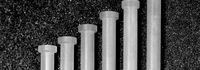

| Outside diameter / Inside diameter | Maximum length | Temperature measurement in different depth areas is available with insulating the thermocouple wires within the protection sapphire tube with sapphire capillaries  |

| 2.1 / 1.3 mm ± 0.2 mm | 1750 mm | |

| 4.8 / 3.4 mm ± 0.15 mm | 1800 mm | |

| 6 / 4 mm ± 0.15 mm | 1800 mm | |

| 8 / 5 mm ± 0.15 mm | 1800 mm | |

| 10 / 7 mm ± 0.2 mm | 1400 mm | |

| 13 / 10 mm ± 0.2 mm | 1400 mm |

Sapphire tubes are sealed by contininuing the crystal growing process. This assures flawless material inegrity and faultless structure throughout the whole thermocouple tube.

E-mail us at sales@crytur.cz for your enquiry regarding discounted short sapphire tubes.