Tempered Sapphire

Sapphit™ is a single crystal of Al2O3 that is forced to crystalize into the desired shape/profile by Crytur‘s proprietary and patented technology.

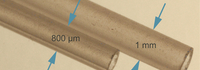

Crytur's Sapphit™ sapphire tubes patented production using the EFG growth method delivers the highest quality for instrumentation and measuring. The unique characteristics of a shape-grown single crystal make Sapphit™ the right choice for extremely demanding applications. Sapphit™ sapphire tubes are the result of the state-of-the-art manufacturing process involving material tempering, which minimizes any inner tension and guarantees perfect material homogeneity.

Perfect crystal lattice is the key to Sapphit™ sapphire tubes high durability. Unlike ceramic casings, sapphire structure is perfectly homogenous throughout the whole product. Ceramic materials on the other hand consist of microscopic crystal grains sintered together. The grain boundaries create weak points in the structure where corrosion begins and ceramic components deteriorate much faster.

|

|

|

Sapphit™ sapphire tubes - perfect homogenous structure |

Ceramics - polycrystalline grain structure with grain boundaries |

Comparing single crystal Sapphit™ to ceramics would in a way be like comparing glass to very fine sandstone or icicle to snow cone. Sapphit™ is by far a superior product.

SAPPHIT™ SAPPHIRE TUBES |

CERAMIC TUBES |

|

100% Gas-tight with high pressure resistance |

No or limited gas tightness |

|

Operating temperature up to 2000°C |

Most manufactureres recomend to use in temperatures under 1700°C |

|

High material purity preventing process contamination - 100x higher purity than high-purity pranslucent ceramics |

Lower material purity |

|

High corrosion resistance |

Low corrosion resistance |

|

Perfect shape stability - no bending or shape changes until reaching the melting point at 2053°C |

Shape deformation at higher temperatures |